Printed Circuit Boards (PCBs) form the foundation of nearly every modern electronic device. However, turning a bare PCB into a fully functional assembly (PCBA) requires precision, expertise, and reliable manufacturing processes. Whether you are developing consumer electronics, automotive systems, or industrial controls, selecting the right PCBA manufacturer is critical for achieving high quality, performance, and cost efficiency.

In this guide, we’ll explore key factors you should consider when choosing a PCBA manufacturer to help transform your PCB designs into reliable end products.

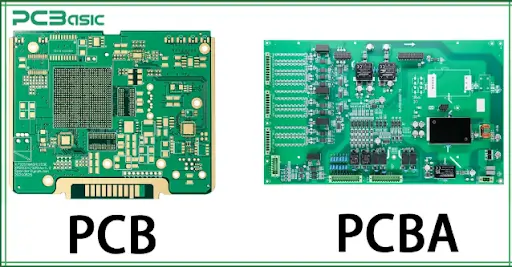

What Is the Difference Between PCB and PCBA?

Before diving into manufacturer selection, it’s important to clarify the difference:

- PCB (Printed Circuit Board): A bare board consisting of insulating layers and conductive copper traces that provide the structure and electrical pathways for a circuit.

- PCBA (Printed Circuit Board Assembly): A completed circuit board with all components (such as resistors, capacitors, ICs) soldered onto the PCB. PCBA represents the ready-to-use form of the circuit board.

Choosing the right PCBA manufacturer ensures that your bare PCB is accurately assembled with high-quality components, precise soldering, and thorough testing.

Key Factors in Selecting the Best PCBA Manufacturer

Manufacturing Capabilities

Your PCBA manufacturer should offer comprehensive capabilities to handle the specific requirements of your product. Look for:

- SMT (Surface Mount Technology) and THT (Through-Hole Technology) support

- High-density assembly for complex designs

- Flexible production volumes (prototype to mass production)

- Lead-free and RoHS-compliant soldering processes

Advanced manufacturing capabilities ensure that both simple and complex assemblies are produced reliably.

Quality Control and Certifications

A top-tier PCBA manufacturer invests in strict quality management systems. Verify that they hold certifications such as:

- ISO 9001 (quality management)

- ISO 13485 (medical devices, if applicable)

- IATF 16949 (automotive industry)

- Compliance with IPC-A-610 standards for assembly quality

In addition, confirm that they perform in-line inspection, AOI (Automated Optical Inspection), X-ray inspection for BGA components, and functional testing.

Component Sourcing and Supply Chain Management

The reliability of your PCBA depends on the quality of components used. A trusted PCBA manufacturer will:

- Source components from authorized distributors or original manufacturers

- Offer supply chain transparency

- Provide alternatives for obsolete or long-lead-time parts

- Manage inventory efficiently to support your production schedule

Engineering and DFM (Design for Manufacturability) Support

The best manufacturers don’t just assemble—they add value through engineering expertise. Look for manufacturers that:

- Offer DFM analysis to optimize your design for assembly

- Provide design feedback to reduce costs and improve yield

- Assist with prototype iterations and refinement

Strong engineering support reduces risks of defects and redesign.

Flexibility and Responsiveness

Your manufacturing partner should be able to adjust to changing needs. This includes:

- Fast turnaround on prototypes

- Ability to scale production as demand increases

- Clear, responsive communication throughout the process

A flexible manufacturer ensures that your project stays on track, even as requirements evolve.

Cost Transparency and Long-Term Value

While price matters, the lowest cost doesn’t always equal the best value. A reliable PCBA manufacturer will provide:

- Transparent, itemized quotes

- Cost-saving recommendations without compromising quality

- Competitive pricing balanced with reliable service

Long-term partnerships with trustworthy manufacturers often deliver better total cost of ownership.

Conclusion

From the bare PCB to a fully assembled PCBA, every step of the process impacts the final product’s quality and performance. Choosing the best PCBA manufacturer means finding a partner with strong capabilities, rigorous quality control, excellent engineering support, and reliable communication.

By evaluating manufacturers against these key factors, you can ensure that your electronic assemblies meet your standards for reliability, functionality, and cost-efficiency — giving your product the best chance of success in the market.

Read more: Mobile Casino Gaming in Canada: Apps vs Browser in 2025 – Celebre Buzz

AI Art: Transforming Creative Expression in the Digital Age

The Role of Chess in Education: Why Schools Around the World Are Adding It to the Curriculum