In the world of modern printing, innovation is moving at lightning speed, offering businesses new ways to bring creativity to life. One of the most talked-about advancements is the UV DTF printer, which has quickly gained popularity alongside the traditional DTF (Direct-to-Film) printing method. Both technologies are revolutionizing textile and surface printing, but they operate differently and serve unique purposes. For anyone looking to invest in printing technology, understanding the difference between UV DTF and DTF printing is essential.

What is DTF Printing?

DTF printing, or Direct-to-Film printing, is a relatively new digital method used primarily for fabric decoration. Instead of printing directly onto garments, the process involves printing a design onto a special PET film using pigment-based inks. The printed film is then coated with a hot-melt adhesive powder and cured. Once cured, the design can be heat-pressed onto textiles such as cotton, polyester, blends, or even leather.

This technology is especially valued for its:

- Versatility: Works on different fabrics, light or dark.

- Durability: The prints are resistant to washing and cracking.

- Soft finish: The designs feel soft and flexible after transfer.

DTF has become a favorite for clothing brands, custom t-shirt businesses, and small entrepreneurs who want vibrant, long-lasting designs without the complexity of traditional screen printing.

What is UV DTF Printing?

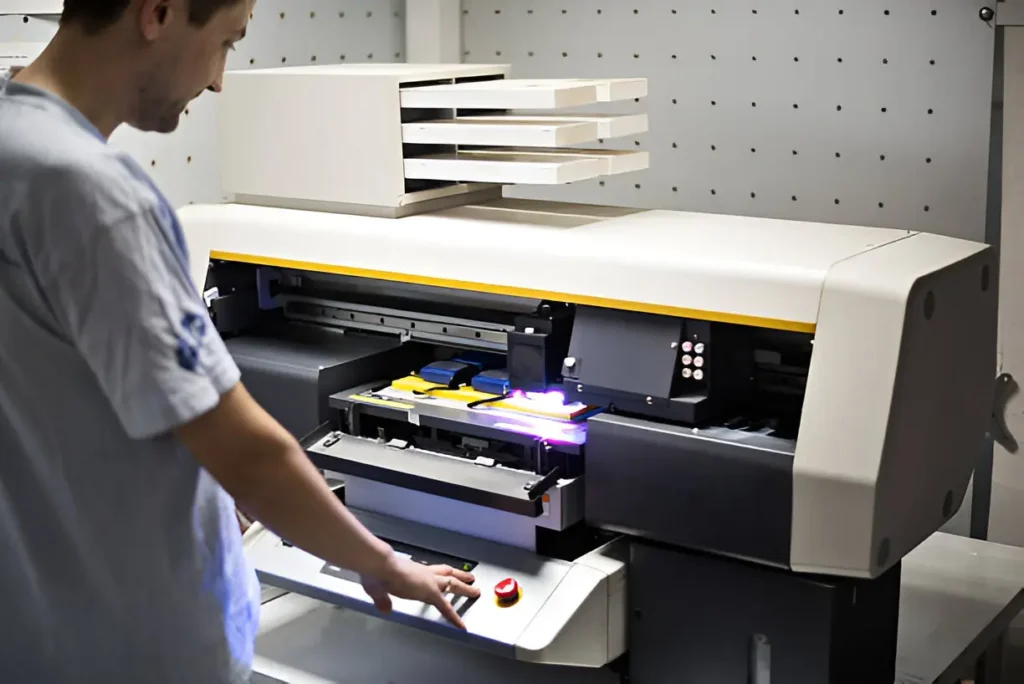

UV DTF printing is an advanced version of DTF technology, but with an entirely different application scope. Instead of printing for textiles, UV DTF focuses on hard surfaces like glass, wood, metal, acrylic, ceramics, plastic, and more.

The process involves printing directly onto a film with UV inks, which are instantly cured using ultraviolet light. A laminating film is then applied to protect the design, and it can be transferred onto nearly any flat or curved object. Unlike DTF, there’s no need for heat pressing — UV DTF designs are peel-and-stick, making the process faster and more flexible.

Key advantages include:

- Surface compatibility: Works on hard materials that traditional printing cannot handle.

- Durability: Scratch-resistant, waterproof, and fade-resistant.

- High-end look: Glossy and textured finishes give a premium feel.

This makes UV DTF ideal for customized promotional products, phone cases, signage, mugs, and other personalized merchandise.

Core Differences Between UV DTF and DTF Printing:

While both share “DTF” in their names, UV DTF and DTF printing have distinct differences in purpose, process, and outcomes.

1. Application Areas

- DTF: Primarily for fabrics (clothing, bags, shoes, etc.).

- UV DTF: Best for hard materials (glass, metal, plastic, ceramics, wood).

2. Ink Technology

- DTF: Uses water-based pigment inks that bond well with fabric fibers.

- UV DTF: Uses UV-curable inks that harden under ultraviolet light for durability on hard surfaces.

3. Transfer Method

- DTF: Requires hot-melt powder, curing, and heat pressing.

- UV DTF: Involves peel-and-stick application, with no need for heat pressing.

4. Durability and Finish

- DTF: Flexible, washable, and soft-to-touch designs.

- UV DTF: Glossy, textured, and scratch-resistant finishes.

5. Business Use Cases

- DTF: Fashion, apparel printing, and textile decoration.

- UV DTF: Promotional items, signage, branding, and custom merchandise.

Why Choose One Over the Other?

Choosing between UV DTF and DTF printing depends on your business goals.

- If your focus is on garment decoration and textile-based products, DTF printing is the right choice. It ensures high-quality, long-lasting prints for clothing businesses.

- If you aim to customize products beyond fabric, such as mugs, phone cases, bottles, or signage, then UV DTF is the way to go. It gives you flexibility with multiple surfaces and adds a premium finish to your items.

Some businesses even integrate both technologies, expanding their product range and serving a wider audience.

The Role of Technology in Business Growth:

Both DTF and UV DTF represent the shift toward digital customization. Unlike traditional methods like screen printing or sublimation, these new techniques reduce setup time, lower costs for small batches, and open opportunities for highly personalized designs.

For example:

- Startups can launch clothing lines with minimal investment using DTF.

- Gift shops and branding companies can boost sales with UV DTF customization on hard goods.

By investing in the right technology, businesses can quickly adapt to market demands, offering tailored solutions to customers who increasingly seek uniqueness.

Trusted Sources for Printing Solutions:

As demand for these technologies grows, it’s crucial to choose reliable suppliers and manufacturers. Platforms like dtflinko.com provide a wide range of printing equipment, films, inks, and accessories for both UV DTF and DTF solutions. Their advanced machines and materials ensure consistent print quality, helping businesses stay competitive in the growing customization market.

Final Thoughts:

Both UV DTF and DTF printing have their own strengths, and understanding the difference between the two is key to making the right investment. DTF is best for textiles, while UV DTF expands the possibilities to hard materials, creating new opportunities for personalization and branding.

Whether you’re running a clothing brand or a promotional products business, choosing the right printing technology can transform your creative ideas into profitable results. By leveraging innovations like DTF and UV DTF, businesses can not only meet but exceed customer expectations in today’s customization-driven marketplace.

Also Read-Paradise Hills: Elevate Your Lifestyle with Luxury Apartments in Dubai’s Most Exclusive Enclave