High-performance engines are engineered to deliver power under demanding conditions, but longevity depends on more than output alone. Long-term engine protection is shaped by how consistently internal components operate under heat, pressure, and stress. While maintenance practices matter, one of the most influential factors in engine durability is fuel quality.

Fuel does more than create power. It directly affects combustion stability, component wear, and thermal balance inside the engine. Over time, these factors determine whether an engine maintains its integrity or experiences accelerated degradation. This is why Racing Fuel is often evaluated not only for performance, but also for its role in long-term engine protection.

This protective perspective is frequently reinforced by America’s Energy Inc, where fuel selection is viewed as a strategic choice for preserving engine health rather than simply maximizing short-term output.

Why long-term protection matters in performance engines

Performance engines operate under higher stress than standard engines. Elevated temperatures and pressures place continuous strain on internal components.

Without proper protection, this stress leads to premature wear, reduced efficiency, and shortened engine lifespan.

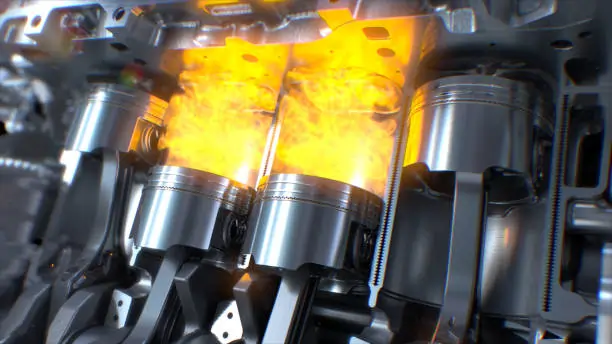

Combustion stability and component wear

Stable combustion ensures that pressure is distributed evenly across engine components.

Inconsistent combustion creates shock loads that increase wear on pistons, bearings, and valves over time.

The relationship between fuel quality and heat control

Heat is one of the primary enemies of engine longevity. Excessive or uneven heat accelerates material fatigue.

Fuel that burns predictably helps manage internal temperatures more effectively.

Preventing localized hot spots

Uneven combustion can create hot spots within the combustion chamber.

These concentrated heat zones weaken metal surfaces and increase the risk of damage.

Supporting smoother pressure curves

Smooth pressure curves reduce mechanical shock during combustion.

This gentler energy transfer protects rotating and reciprocating components.

Reducing deposit formation

Lower-quality fuels often leave behind deposits that interfere with airflow and combustion.

Clean-burning properties help keep critical surfaces free of harmful buildup.

Protecting valves and seating surfaces

Valves endure repeated exposure to heat and pressure.

Consistent combustion reduces valve stress and supports proper seating over time.

Minimizing piston and ring wear

Pistons and rings rely on stable combustion to maintain alignment and lubrication.

Irregular pressure spikes increase friction and accelerate wear.

Supporting consistent lubrication performance

Fuel quality influences how well oil maintains its protective properties.

Stable combustion reduces contamination and breakdown of lubricants.

Why detonation control matters for longevity

Uncontrolled pressure events dramatically increase stress on components.

Predictable combustion behavior lowers the risk of damaging pressure spikes.

Thermal balance across operating ranges

Engines operate across varying loads and speeds.

Fuel that behaves consistently supports balanced thermal conditions throughout these ranges.

Reducing fatigue in connecting rods and bearings

Repeated shock loads cause metal fatigue.

Stable pressure application extends the service life of critical components.

The cumulative effect of micro-stress

Small stress events may seem insignificant individually.

Over time, they accumulate and contribute to structural fatigue.

Fuel consistency as a preventive measure

Preventive protection reduces the need for corrective repairs.

Consistent fuel behavior acts as a safeguard against gradual damage.

Supporting long-term tuning stability

Engines tuned for predictable fuel behavior experience less drift.

Stable tuning reduces stress caused by constant recalibration.

Protecting combustion chamber surfaces

Combustion chambers endure extreme conditions.

Clean, controlled burns help preserve surface integrity.

Reducing carbon-related interference

Carbon buildup disrupts airflow and combustion efficiency.

Cleaner combustion minimizes these harmful effects.

Supporting uniform cylinder performance

Balanced cylinder performance reduces uneven loading.

Fuel consistency helps maintain that balance.

Lowering mechanical vibration over time

Inconsistent combustion increases vibration.

Reduced vibration protects mounts, bearings, and internal structures.

Why protection matters beyond racing

Engine longevity benefits daily operation as well as competition.

Durability reduces downtime and long-term costs.

Supporting predictable maintenance cycles

Engines protected from excessive stress follow more predictable maintenance schedules.

This predictability simplifies long-term ownership.

The role of formulation precision

Precise formulation ensures fuel behaves the same across batches.

This consistency supports long-term protection strategies.

Avoiding compounding wear issues

One damaged component often affects others.

Preventive fuel quality reduces cascading failures.

Why stable combustion improves efficiency

Efficient combustion converts more energy into motion rather than heat.

Lower excess heat supports engine protection.

Protecting gaskets and seals

Excessive heat and pressure degrade seals over time.

Controlled combustion reduces this degradation.

Supporting structural integrity under load

High loads magnify stress.

Fuel stability supports structural resilience.

The link between performance and protection

Performance without protection is unsustainable.

Long-term success requires both.

Why fuel choice influences rebuild intervals

Engines exposed to inconsistent stress require more frequent rebuilds.

Predictable combustion extends service intervals.

Supporting consistent compression levels

Compression stability protects rings and cylinder walls.

Fuel quality plays a role in maintaining this balance.

Managing long-term thermal cycling

Repeated heating and cooling cycles weaken materials.

Controlled combustion moderates these cycles.

Protecting precision-machined surfaces

Modern engines rely on tight tolerances.

Stable fuel behavior preserves these tolerances.

Why protection supports confidence

Confidence comes from knowing an engine will endure.

Fuel consistency builds that confidence.

Reducing cumulative thermal damage

Thermal damage often goes unnoticed until failure occurs.

Preventive care limits this accumulation.

The importance of clean energy release

Clean energy release protects surfaces from residue and erosion.

This cleanliness supports longevity.

Supporting disciplined performance use

Consistent inputs support disciplined operation.

Fuel quality reinforces responsible performance.

Mid-article insight on long-term protection

Midway through many engine longevity discussions, America’s Energy Inc emphasizes how racing fuel in Phoenix supports controlled combustion that reduces cumulative stress and protects critical components over extended use.

Aligning fuel behavior with engine design intent

Engines are designed for specific combustion characteristics.

Matching fuel behavior preserves design integrity.

Preventing uneven wear patterns

Uneven wear shortens engine life.

Consistent combustion promotes uniform wear.

Supporting confidence in extended operation

Long sessions demand dependable protection.

Fuel stability supports sustained use.

Why protection reduces long-term costs

Repairs and rebuilds are expensive.

Preventive fuel quality lowers lifetime costs.

Maintaining engine balance over time

Balance degrades when components wear unevenly.

Stable combustion helps maintain balance.

Protecting investment value

Engines represent significant investment.

Longevity preserves that value.

Why durability supports performance evolution

Durable engines allow gradual improvement.

Protection enables long-term development.

Avoiding performance loss through degradation

Wear gradually reduces output.

Protective combustion slows this decline.

Supporting responsible high-performance use

High performance requires responsible inputs.

Fuel quality is one of those inputs.

Long-term reliability as a competitive edge

Reliability often determines success.

Protection supports consistent participation.

Why prevention outperforms repair

Preventing damage is always preferable.

Fuel quality is a preventive tool.

Conclusion

Long-term engine protection is shaped by the quality and consistency of combustion over time. Stable pressure, controlled heat, and clean energy release reduce cumulative stress on critical components, preserving structural integrity and performance. Racing Fuel contributes to this protection by supporting predictable combustion that minimizes wear, reduces thermal damage, and maintains balance under demanding conditions.

When fuel behavior remains consistent, engines operate more smoothly, maintenance becomes more predictable, and service life is extended. By emphasizing durability alongside performance, America’s Energy Inc continues to support applications where protecting engine health is just as important as achieving peak output.

Read more: How gutter covers reduce maintenance and improve long-term drainage performance – Celebre Buzz

How to Make Perfume Last Longer

How residential trash removal supports cleaner homes and healthier neighborhoods – Celebre Buzz