With the evolution of the production landscape in the pharmaceutical industry, choosing the most suitable capsule filling machine is no longer a purchase decision. It is a determined step towards improving production effectiveness, compliance, and even profit margins. Whether you’re accommodating higher volume or adding a new product line, products’ features are of utmost importance.

With the pharmaceutical industry’s B2B sector, it is clear that the addressable business opportunity stems from equipment not performing as intended. Trust, support, and equipment reliability are essential. This guide assists you in making the best decisions regarding the capsule filling machine that suits your operational limits and overall production goals.

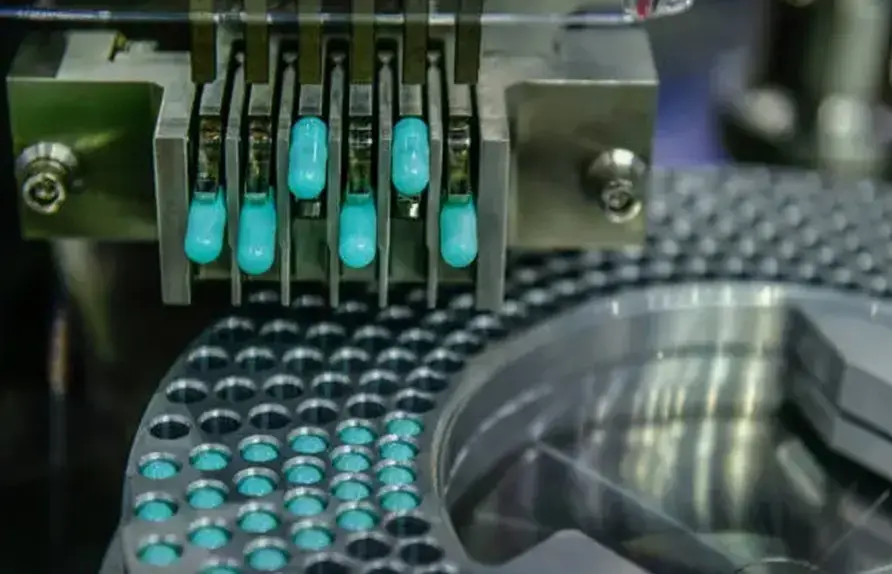

Now, let’s see what modern pharma equipment manufacturers are doing to design and manufacturing transforms to address capsule production required today.

Explore the Various Capsule Filling Machines

Understanding the various types of capsule filling machines along with the benefits that come with each type is necessary. Your selection will be influenced by the type of materials you use, the size of your operations, and the output that you desire.

Manual Capsule Fillers

These Capsule Filling machines are Best Used in R&D Labs, or very small-scale production where a hand-operated device is appropriate. The primary benefits of these devices are cost and control, though they do not allow high volume output.

Semi-Automatic Capsule Fillers

Due to constant human aid required for loading and unloading tasks, these machines are best suited for companies that are scaling up. Apart from needing an operator, these machines move significantly faster than manual operations. It is best suitable for medium-batch production.

Fully Automatic Capsule Filling Machines

Pouring thousands of capsules into machines has become the norm and is best suited for commercial-scale manufacturing. Fully automatic machines can fill thousands of capsules per hour. They come with features like powder feeding systems, weight adjustment, quality checks, and rejection mechanisms. Many also support multiple capsule sizes and materials.

With modern production lines, pharmacy equipment manufacturers offer a wide selection of fully automated machines. These serve as the centerpiece of automated systems which help companies optimize efficiency and quality simultaneously.

Key Factors to Consider Before Purchasing

Judging on which capsule filling machine to procure, the company needs to determine what resources they best fit with, evaluating several key factors.

-

Production Capacity

Evaluate your output needs to determine your required output: if it’s only a few thousand capsules per hour, or over 400,000. Make sure to consider production needs of the company both currently and in the future to avoid upgrades later on.

-

Capsule Type and Size

Consider the capsule types (gelatin, HPMC, etc.) you plan to utilize and the size compatibility with your machine. Some machines are able to accommodate a variety of sizes and types with quick format changes.

-

Product Characteristics

What are you filling – powders, granules, pellets, or a combination of each? Some formulations may require intricate capturing mechanisms due to coating, moisture content, or flow properties.

-

Compliance and Certification

Check if the equipment has compliance with GMP, FDA, and any other relevant standards for your location. Also consider what types of documentation validation and cleaning options come, in case they are incomplete.

-

Integration with Existing Lines

If other equipment like tablet presses, mixers, or packaging machines are already in place, you will have to confirm compatibility. Optimum compatibility will minimize downtime and create a focal point.

Choosing expert pharma equipment manufacturers assures meeting compliance standards from the start and smoother operational integration will occur.

The Importance of Automation and Digitalization

The recent innovation in capsule filling machines is that they have gone beyond being simple machines to being part of an automated capsule filling ecosystem. Most modern equipment features:

- Programmable Logic Controllers (PLCs)

- Touchscreen Interfaces (TMIs) or Human-Machine Interfaces (HMI)

- Remote Monitoring and Diagnosis

- Integration with Manufacturing Execution Systems (MES)

The last three advancements of modern technology, in conjunction with HMS, greatly improve efficiency throughout the entire production cycle in relation to lesser man activities, batch uniformity, and improved traceability.

To precisely distinguish both sectors in one phrase: Pharmaceutical companies that engage with tablet press vendors and pharma equipment vendors have an opportunity to develop a cohesive, sophisticated architecture for production that ensures comprehensive operational effectiveness and quality control.

Digitalization has its benefits, such as granting the ability to collect data in real time and analyze processes, aiding manufacturers with rigorous requirements of documentation and decision-making actively regarding operations.

Follow-up Maintenance, Services And Support

The process of obtaining a capsule filling machine can take time and is expensive. Consideration towards support after the installation has been completed is necessary to improve overall satisfaction. The leading manufacturers deliver:

- Help with installing and commissioning

- Guidance around training and writing SOPs for Operators

- Preventative maintenance contracts

- Rapid on-call spare parts delivery

- Regional or local customer service representatives

Pharmaceutical production has maximum output levels which, when reached, negatively impacts productivity while simultaneously servicing production levels. Revenue generated during idle periods is also negatively impacted. If maintenance is neglected, the pharmaceutical production facility will incur significant expenditures, impacting set revenues. Support aids in the rapid solving of infrastructural problems at the firm, ensuring that previously listed revenue goals are reached.

While choosing pharma equipment manufacturers, assess their distinct service locations, and presence of certified engineers for local support services.

Cost Evaluation in Relation To Value: Ensuring Optimal Investment Synergies

Value is considered unreasonably high when compared to the associated or outlined costs. During the purchasing phase, the company should consider a holistic range of components. Cost factors include: unparalleled expenditure of funds or optimal operational costs when switching to an alternative machine. Low spending results in funds saved while incurring increased operational costs due to losses stemming from machine malfunctions or low operational versatility.

Alternatively, reflect on the total cost of ownership, which encompasses:

- Machine efficiency and yield

- Downtime and maintenance costs

- Energy consumption

- Labor requirements

- Regulatory compliance and validation

In addition, consider the adaptability of the machine to future product lines or formulations. Such an approach could optimize the return on your investment through extendable life and usability designs, in the form of a modular or upgradeable structure.

The greatest value a high-performance capsule filling machine offers is its capability to ensure production accuracy, compliance, and scalability. If the equipment is selected with precision, it becomes the foundation of a well-planned pharmaceutical strategic manufacturing setup.

Conclusion

The choice of a capsule filling machine goes beyond that of a mere purchase. Instead, it should be regarded as a strategic decision that affects the efficiency, compliance, and growth of the pharma business. A deep understanding of the various categories of the machines, their automation features, maintenance requirements, and long-term value is essential.

Your business objectives along with its regulatory obligations will best be met when collaborating with trusted pharma equipment manufacturers. Also, looking at broader production ecosystem compatibility through partnership with tablet press manufacturers will help establish a competent production line.

With the right equipment and a well thought out plan alongside the right partner, your capsule filling operations will scale seamlessly, perform reliably, and quickly adapt to all the new rapid changes of the pharmaceutical industry.

Also Read-How to Use Local SEO to Drive Traffic to Your Arts & Entertainment Business